As the most important part of the lighting test, the main function of the goniophotometer is to measure the absolute luminous intensity. At the same time, it can measure other parameters such as lumen and illuminance. Because of the different testing principle, compared with the integrating sphere spectroradiometer system, the device is more suitable for the measurement of the overall luminaire.

Carrying the measurement with goniophotometer, the standard darkroom is needed. If the darkroom does not meet the requirements, it is likely to affect the final test results, which will lead to the deformation of distribution curve and the inaccurate results of lumen. And the final IES file will not meet the requirements, that will affect the final test results.

According to the requirements of the test environment in LM-79 and CIE-70, this paper makes a brief introduction to the selection of darkroom:

Temperature requirements:

According to the requirements of CIE-70 and LM-79, when carrying the measurement with goniophotometer, the ambient temperature should be around 25°. For the light source with obvious influence on the temperature, the temperature tolerance should be ±1°and the other light sources are ±3°. If the test is carried out at different ambient temperatures, the temperature should be stated.

In order to meet the requirements of test environment, it is usually required to install air-conditioner in the darkroom to control the temperature. At the same time, a thermometer with a precision of 0.01°is needed to use to calibrate the temperature.

Stray light requirements:

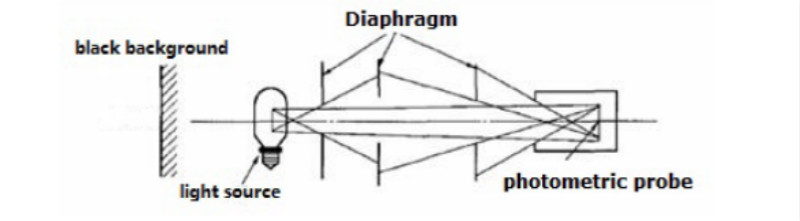

Stray light has a bad effect on the test results, so it is recommended that the diaphragm should be used between the light source and the photometric probe to prevent stray light, but the diaphragm mustn’t block the direct light between the probe and the light source.

It is possible to determine the ratio of stray light by placing a minimum possible size screen in the middle of the light source and the photometric probe. The screen blocks the direct light from the light source to the photometric probe.

The test of light intensity distribution should be repeated when the screen is in the corresponding position. The measurement signal at this time is the signal of direct stray light, which should be subtracted from the test result without this screen.

In general, the biggest influence on the test results is the stray light, which will directly lead to the test result of the light intensity distribution curve is not accurate, then the IES or LDT file will not be used naturally. According to the requirements of the standard, the installation principle of the diaphragm is as follows:

According to different models of goniophotometer and different size of customers’ darkroom, Lisun engineers will design the different size diaphragm for customers.

LSG-2000 Goniophotometer with Rotating Mirror

LSG-1700B High Precision Rotation Luminaire Goniophotometer

Requirements for darkroom wall painting:

According to the standard, in the actual test, there is only one light source to be measured in the darkroom. In this case, if the room wall is bright color, or white,or the use of reflective coatings, it will cause stray light to affect the test results. When sending drawings to customers, Lisun usually asks customers to use the matt black coating to paint all the walls. It’s important to note that the most important wall in the darkroom is the wall facing the photometric probe, which is usually the wall behind the goniophotometer host. Stray light will be directly detected in the probe if there is stray light.

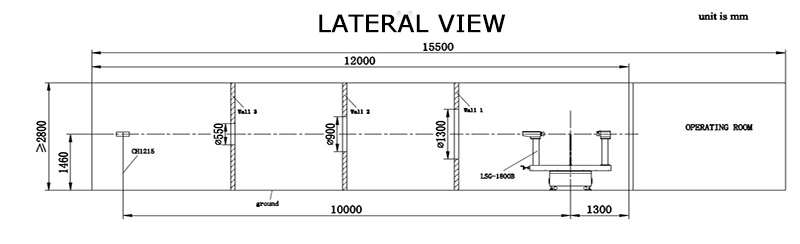

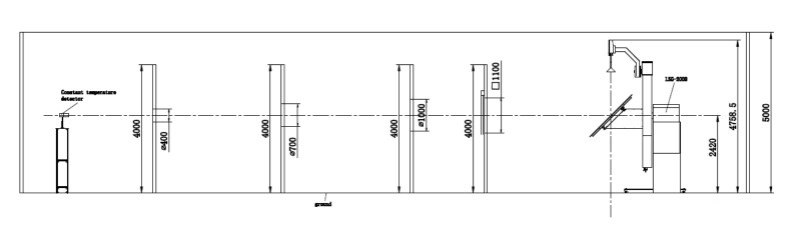

Darkroom size requirements:

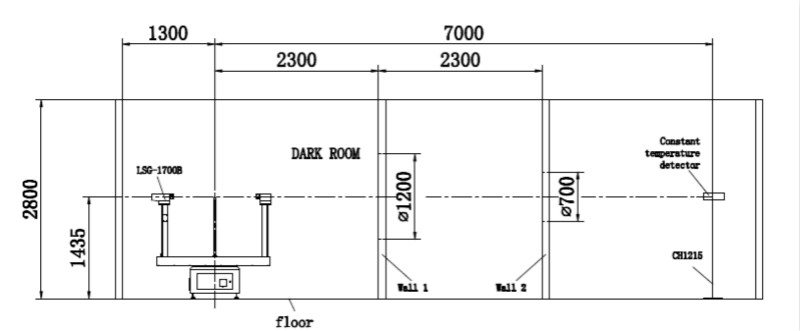

According to LM-79 and CIE-70 requirements, the length of test optical path should be at least for more than 5 times of the diameter of the longest dimension of the test lamp. It means that if the maximum size of the measured light is 1.2 meters, the length of the optical path should be at least 6 meters and plus the position of host and probe, the whole darkroom length should be at least 8 meters. A standard darkroom can guarantee the test accuracy.

The above four requirements are the basic points that the user must pay attention in the preparation of the darkroom. LISUN will also design the darkroom for all customers, and help customers rectify the darkroom to ensure a standard test environment. At the same time, all of LISUN’s LSG-1700B/1800B/2000/3000/5000 goniophotometer are equipped with a constant temperature probe with high precision. Under this premise, when customers prepare temperature control system for darkroom, they can only consider the temperature control system of lamp position, which can greatly save the cost.

The following is the design of standard darkrooms:

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Spectroradiometer, Integrating Sphere, LED Test Instruments, CFL Test Instruments, Photometer and Colorimeter, EMC & EMI Testing, Surge Generator, Electrical Safety Testing, Environmental Test Chamber, Waterproof Test , Dustproof Test Chamber, High and Low temperature Humidity Chamber, Plug and Switch Testing, AC and DC Power Supply.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

中文简体

中文简体