Although the measuring system with integrating sphere and photometric probe has the advantages of simplicity, reliability, stability, etc., it is inconvenient to measure the color, and is not suitable for the measurement of discontinuous spectrum. Now it is rarely used. At present, the preferred method for light color measurement of LED lamps is the measurement system using spectroradiometer integrating sphere system. Based on the measurement theory of integrating sphere, the system can calculate the main wavelength, peak wavelength, half width, red ratio, luminous flux, CCT, CRI, SDCM, Duv, X, Y and other light color parameters by measuring the relative spectral power distribution of a point on the sphere.

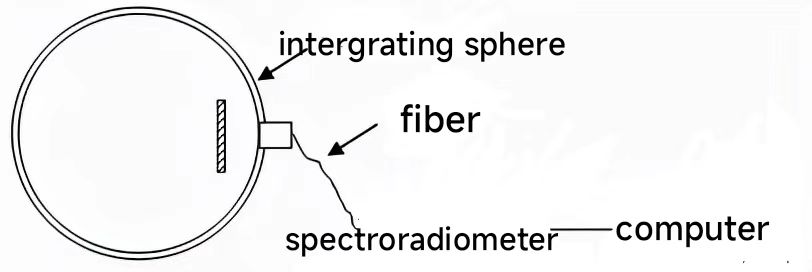

Plan of integrating sphere spetroradiometer system

What are the test methods of spectroradiometer integrating sphere system ?

Spectral photometry and full spectrum method are the measurement methods adopted by most manufacturers, testing institutions and laboratories to measure the light color parameters of light sources. The two measurement methods are to connect the integrating sphere with the spectroradiometer, and compare the standard lamp with the lamp to be measured to obtain the photochromic parameters of the light source to be measured. The two test methods are described below.

1、 Spectrophotometry

Spectralphotometry is used to measure the luminous flux of the measured light source by photometry and the chromaticity parameter by spectrometry.

Photometric measurement of luminous flux is simply to compare the standard lamp with known luminous flux (the value is traceable to the China Institute of Metrology) with the measured light source in the integrating sphere, so as to obtain the luminous flux of the measured light source.

The basic principle of luminous flux measurement is to place the measured light source in the integrating sphere and coat the inner wall of the integrating sphere with a white diffuse reflective layer (spectral reflectance ρ ≥ 0.98), the light emitted by the light source is reflected by the ball wall for many times, so that the illuminance on the whole ball wall is evenly distributed, and the luminous flux projected onto the photodetector through the holes on the ball wall shall be proportional to the total luminous flux emitted by the light source. In order to make the relative spectral sensitivity of the photodetector on the spherical wall conform to the spectral luminous efficiency of the human eye, the method of adding a filter group is generally used for correction. By calculating the propagation and conditions of light in the filter glass group, according to the typical transmittance characteristic curve of known colored glass types, select the colored glass group with appropriate matching curve, calculate the appropriate thickness of each colored glass required for the matching curve according to the formula, and finally correct to obtain the photometric value.

Spectral method is used to measure chromaticity parameters. The spectrometer is generally composed of monochromator spectrophotometer system, photometric detection system and data processing part. First calibrate the spectral analyzer with a standard lamp with known radiation at each wavelength, then release the measured light source, measure the correction of each corresponding wavelength with a monochromator, and then divide the calculated spectral radiation intensity of each wavelength by the maximum spectral radiation intensity to obtain the relative spectral power distribution of the light source to be measured, After the relative spectral power distribution of the measured light source is obtained, it is preferred to correct the difference in spectral power distribution, because the relative spectral power distribution of the standard lamp is different from the spectral power distribution of the measured light source, which will produce luminous flux, and then obtain chromaticity parameters such as excellent coordinates, chromaticity tolerance, related color temperature, and color rendering index.

2、 Full spectrum method

In terms of measurement, the full spectrum method requires that the absolute spectral power distribution corresponding to every 5nm wavelength at 380nm~780nm in the visible band must be known. Within the specified time, the Chinese Academy of Metrology shall calibrate the absolute spectral power distribution corresponding to each wavelength, and calibrate the luminous flux. After the corresponding absolute spectral power distribution of each wavelength is known, The absolute spectral power distribution list is made into the absolute spectral power distribution data of the standard lamp that can be read by the software. The photoelectric detector on the spherical wall window can be removed, and the optical fiber is directly connected to the inner window of the spherical wall. The other end of the optical fiber is connected to the incident slit of the spectral analyzer. The test process is also to ignite the standard lamp and the light source to be measured successively in the integrating sphere. The optical fiber on the spherical wall leads the light into the grating monochromator, The ratio of optical power corresponding to each wavelength of the standard lamp can be measured. After PMT amplification, the ratio of optical current can be obtained, and then the absolute spectral power distribution of the lamp to be tested can be calculated from the LA absolute spectral power distribution P of the standard lamp. According to the conversion formula of radiation and photometric quantity, for the luminous flux of the standard lamp and the lamp to be tested, the relative spectral power distribution is calculated from the absolute spectral power distribution, and then the photoelectric parameters such as excellent coordinates, chromaticity tolerance, relevant color temperature, color rendering index, etc. are obtained by the same method as the spectral photometry.

LISUN lauched LPCE-3 is a CCD Spectroradiometer Integrating Sphere Compact System for LED Testing. It is suitable for single LED and LED luminaires’ photometric, colorimetric and electrical measurement. The measured data meets the requirements of CIE 177, CIE84, CIE-13.3, COMMISSION DELEGATED REGULATION (EU) 2019/2015, IES LM-79-19, Optical-Engineering-49-3-033602, IESNA LM-63-2, ANSI-C78.377 and GB standards.

The Sphere System Configuration:

CCD Spectroradiometer (LMS-7000), Optical Fiber (CFO-1.5M), Digital Power Meter (LS2008R), DC Power Source (DC-S Series), AC Power Source (LSP-500VAS), Integrating Sphere (IS-1.5MA-CASE and IS-0.3M), Standard Light Source (SLS-50W and SLS-10W)

LPCE-2 Integrating Sphere Spectroradiometer LED Testing System is for single LEDs and LED lighting products light measurement. LED’s quality should be tested by checking its photometric, colorimetric and electrical parameters. According to CIE 177, CIE84, CIE-13.3, IES LM-79-19, Optical-Engineering-49-3-033602, COMMISSION DELEGATED REGULATION (EU) 2019/2015, IESNA LM-63-2, IES-LM-80 and ANSI-C78.377, it recommends to using an array spectroradiometer with an integrating sphere to test SSL products. The LPCE-2 system is applied with LMS-9000C High Precision CCD Spectroradiometer or LMS-9500C Scientific Grade CCD Spectroradiometer, and A molding integrating sphere with holder base. This sphere is more round and the test result is more accruacy than the traditional integrating sphere.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

中文简体

中文简体