The traditional light distribution curve commonly used at present] is mostly tested by rotating, which can accurately obtain the light intensity distribution curve of the light source on a two-dimensional plane. However, to correctly reflect the spatial distribution characteristics of the luminous intensity of LED devices, only one or several planar light distribution curves are not enough. Based on the test principle of the traditional light distribution curve of light source, there are generally two methods for testing the light intensity distribution curve of LED devices: one is that the LED is fixed and the photometric detector receiving light rotates and scans around it; The other is that the photometric detector does not move and the LED rotates around the apex of the package shell. Because of the defects of these methods, such as long test time, low measurement accuracy and cumbersome calibration, a new type of test method and device is introduced, that is, the light intensity is received by the CCD photometric detector, and the light intensity signal is converted into an electrical signal by the photoelectric conversion function of the CCD, and then the light intensity map of the inner wall of the entire hemispherical space can be obtained by the imaging system software. The new testing method has the remarkable advantages of fast testing speed, high accuracy, abundant information and intuitionistic.

1、 Rotation method:

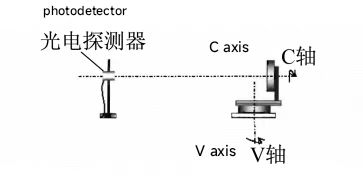

On the basis of the old light distribution curve test method, if an additional axis is added for rotation, a plurality of light distribution curves of different angles can be obtained in sequence by artificial setting, and then transmitted to the computer through data integration, which can be simulated by software, so that a three-dimensional LED light intensity distribution image can be formed. The principle of rotation method is shown in.

Rotation schematic

The rotation method adds a c-axis on the basis of the traditional light distribution curve test method, which is the line from the physical center of the LED optical axis to the detector center. During measurement, the c-axis does not rotate and the v-axis rotates by 180 °, and a planar LED light distribution curve can be obtained. Then rotate the c-axis by a fixed angle (the measurer can make the graduation by himself), fix the c-axis again and rotate the v-axis, so that the light distribution curve on another plane with different angles can be obtained. After multiple measurements (the number of measurements is related to the size of the c-axis rotation graduation), the light distribution curves of multiple planes in the whole space can be obtained. After computer integration, a complete spatial light intensity distribution curve can be obtained.

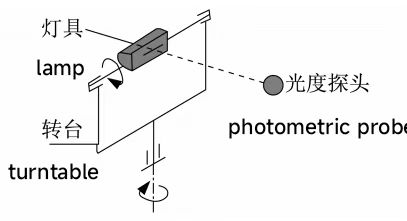

This method is based on first testing the light intensity distribution curve of the plane, then setting a rotation axis, and obtaining the light intensity distribution of the whole space through 360 ° rotation and multiple measurements at multiple angles. Another rotation method is also to set two rotation axes to obtain multiple light distribution curves of different angle planes and integrate them into a spatial light intensity distribution curve. This method is recommended by CIE (International luminous lighting Commission) to test the light intensity distribution of low-power light emitting devices.

360° Rotation axis

2、 CCD based test method:

In this method, CCD image sensor is used as the lighting detector to obtain the light intensity image of the whole LED photosphere with high accuracy, and then through computer software analysis, a more accurate three-dimensional light intensity distribution map of LED can be finally obtained.

The LED light-emitting device to be measured is fixed at the center of the semicircular chamber, a layer of diffuse reflection paint is coated on the inner surface of the hemispherical measurement chamber, a convex mirror is installed near the center of the hemisphere, a partition is installed between the mirror and the led to isolate the direct light of the LED, and the CCD imaging photometer is placed directly above the mirror. During measurement, the LED lamp emits light in the hemispherical surface, which is uniformly reflected on the inner surface of the hemisphere through the diffuse reflection coating of the hemispherical wall. The CCD photometric detector can receive the image of the entire inner wall of the hemisphere reflected by the convex mirror. Because the light intensity at different positions on the inner wall of the hemisphere is different, the light signals received by the CCD at various positions on the inner wall of the hemisphere are also different. Through the photoelectric conversion function of CCD, the received optical signal is converted into an electrical signal and introduced into the computer. The computer software analyzes it to form a simulated two-dimensional image formed by the convex mirror. Then, through the computer software, the light intensity corresponding to each coordinate of the two-dimensional image and the specific position of the inner surface of the hemisphere corresponding to each coordinate of the two-dimensional image coordinate system are further analyzed, and through the accurate calibration of the light intensity, An accurate spatial light intensity distribution map of the LED in the entire space can be obtained.

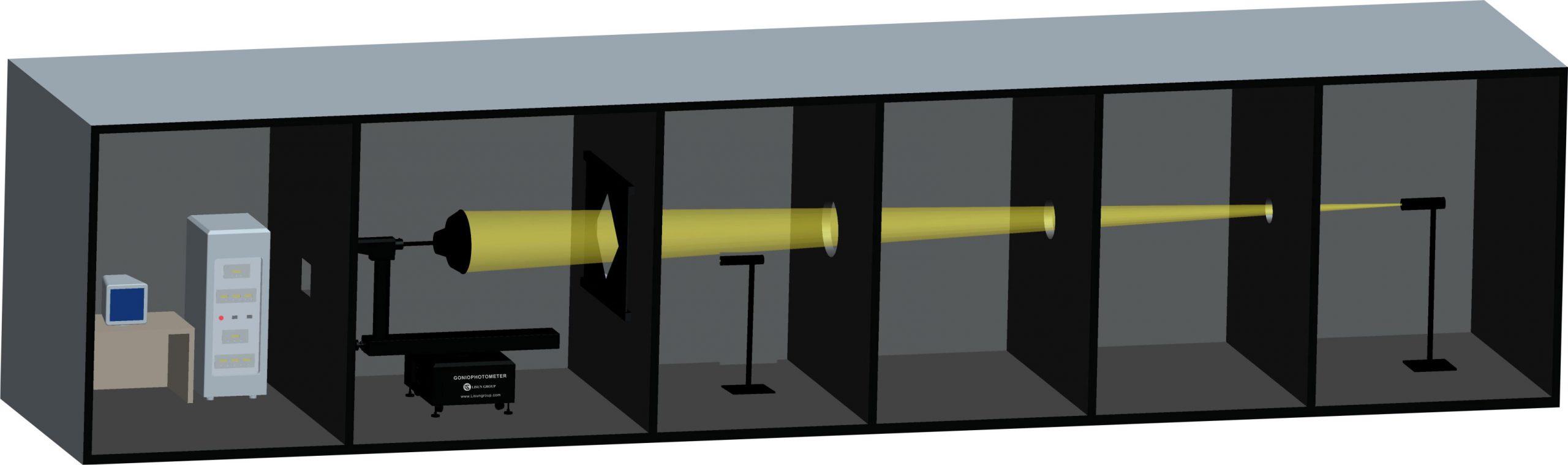

Therefore,LISUN lauched LSG-6000 Moving Detector Goniophotometer (Mirror Type C) was manufactured by LISUN completely meets LM-79-19, IES LM-80-08, COMMISSION DELEGATED REGULATION (EU) 2019/2015, CIE-121, CIE S025, SASO 2902, IS16106 and EN13032-1 clause 6.1.1.3 type 4 requirements. LSG-6000 is the latest upgraded product of LSG-5000 and LSG-3000 in compliance with the requirements of the LM-79-19 standard Clause 7.3.1, its an automatic light distribution intensity 3D curve testing system for measuring light. The measuring distance is from 5m to 30m.

LSG-1890BCCD/LSG-1800ACCD goniospectroradiometer is high precision automatic goniophotometric instrument for luminous intensity distribution measurement with facility for rotating the light source. The LSG-1890BCCD/LSG-1800ACCD can do the spatial CCT test and the intensity distribution test. It is for industrial laboratory photometric data measurement of luminaires such as LED luminaires, LED Plant Lighting, HID luminaires, fluorescent lamps and so on.

LSG-1890B/LSG-1800A goniophotometer is automatic goniophotometric instrument for luminous intensity distribution measurements with facility for rotating the light source. The LSG-1890B/LSG-1800A uses a constant temperature detector, Japanese motor and German precision angle coder which keep the test results with high accuracy. It is for industrial laboratory photometric data measurement of all kinds of luminaries such as LED luminaries, HID lamps, fluorescent lamps and so on.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

中文简体

中文简体