LED has the features of long time. According to different power drivers and use conditions, the life of LED can be up to 50,000 hours pr more. LED will not extinguish directly like other light source but decay gradually. Therefore, luminous decay will lead to output low light after long time use, which will make products not meet requirements. And how to use TM-21 to estimate LED luminaries life?

In order that LED industry persons have a clear concept of TM-21 and learn how to use TM-21 to estimate LED products. We will make 4 programs to explain the application and prediction method of LM-80-08 and TM-21-11:

Step 1: LED components manufacturers do at least 6,000 hours test at 3 temperatures (55C°/85 C°/Optional Temperature) for LED Source (Package/Array/Module) according to LM-80-08.

Required samples number: (Related to the prediction time)

Test Time Requirement (Related to Prediction Accuracy)

At least 6,000 Hours, recommend 10,000 Hours, you should obtain the LED light attenuation information every 1,000 hours, interval time is shorter(such as 500 hours), which can improve the accuracy of the prediction time.

Step 2: Predict 3 test temperatures (55C°/85 C°/Optional Temperature) long life information according to TM-21-11.

Obtain the average value of experiment data at each temperature, the time rules to take test information as follow:

| D Test Time(Hour ) | Take out the data principle |

| 6,000~10,000 | 1. Take out the last 5,000 hours to calculate2. 0~1,000 hours data do not use(LED Unstable Period) |

| >10,000 | 1. Take out last 50% that is D/2~D to calculate |

Use Exponential Least Squares Curve-Fit to get Slope m and Intercept b, when calculate m and b, the interval is denser if test time is longer, its accuracy will increase and then calculate the value of B and α.

y=mx+b, B=exp(b), a=-m

According to formula, calculate the 70% lumen maintenance life time value at every temperature experiment under ENERGY STAR standard.

L70: Time to 70% lumen maintenance

Use sample number in Step 1 to predict multiple times standard to judge:

| Sample Number(Per Temperature) | TM-21 Prediction Multiple Time |

| ≥20ea | 6 times of the test time |

| ≥10ea,<20ea | 5.5 times of the test time |

| <10ea | Not applicable for TM-21 |

Representation: L70(6K) = XX,XXX hours

(6K) : LM-80 Test Time; (6K)=6,000 Hours; (10K)=10,000 Hours

XX,XXX Hours : Sample≧20ea, Test Time=6,000, Predict 6 times to 36,000 hours

Use Exponential Formation to calculate the lumen maintenance of every time, and then draw the prediction life curve at every test temperature according to the calculated data.

Step 3: Obtain In Situ Temperature of this LED devise in LED luminaries.

Please refer to ISTMT(In Situ Temperature Measurement Test) formula to obtain the temperature of LED device in LED lumunaries, this test temperature position must be same with Ts set position of LM-80-08, the temperature data taken out is called TMPLED(LED Temperature Measurement Point).

Step 4: Use the calculation results of TMPLED and TM-21 to do Interpolation calculation, to obtain the estimated life value of TMPLED.

Select two close-in temperature points cladding in TMPLED from 3 test temperature points as calculation datum point.

Calculate Arrhenius Model temperature acceleration parameter A and get Decay Rate: α and Fixed value parameter B0.

Use upper formula to calculate the L70 value of TMPLED, same formula represents the result of TMPLED.

L70(6K) > XX,XXX hours

Set into relevant time value and draw the life time prediction curve of TMPLED and 3 Ts.

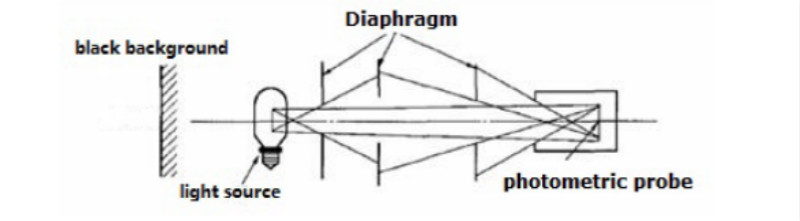

Lisun LEDLM-80PL LED Lumen Maintenance and Aging Life Test System is designed according to IES-LM-80 standards. This system combines Arrhenius Model, which can make users predict L30 and L70 etc lumen maintenance by software after hundreds to thousands of hours test.

Lisun Electronics (Shanghai)Co.,Ltd is lead In lighting test equipment, EMI/EMC test system and safety test instrument. Its quality system has been strictly certificated by ISO9001:2008. The Lisun Group products have been authenticated by the third party lab and were by CE certificate. As a CIE supportive membership, all of the test instruments produced by Lisun Group were designed according to CIE standards.

中文简体

中文简体